|

|

Student Corner: The Past, Present, and Future of Wood ConstructionBy CED Program Interns & StudentsPublished November 17, 2016Did you know that the world’s oldest wooden structure is found in Japan, the Horyu Temple, and has managed to withstand rain, wind, and earthquakes for over 1,300 years? Although wood construction dates all the way back to Stone Age! For thousands of years’ humans have relied on wood to build structures because of its strength and durability. The benefits to wooden structures are plenty. One, they weigh about a quarter of the weight of equivalent concrete material thus requiring a smaller foundation. In downtowns with decreasing land and increasing land costs, this could be a major benefit. Plus, building with wood can be cheaper and wood structures act as CO2 sinks absorbing and storing carbon dioxide emissions. Although wood is costlier per cubic foot than steel-and-concrete, building with timber is faster potentially resulting in a cheaper construction cost overall and boosts the efficiency of the building. Ultimately, building with wood makes more economic sense the taller the building. There are plans for wooden skyscrapers upwards of eighty stories! One Vancouver architect, Michael Green, likened the current age “to the beginning of the steel revolution 120 years ago.” Regardless, many American cities do not allow wood structures past 5 stories. Multifamily Construction The International Building Code (IBC) is a building code model that has been adopted by most of the United States. This code outlines the constraints of different construction materials used in mid-rise buildings. While there are other construction types, the following table represents more reasonable multifamily construction types for products likely to be built across NC. One way to boost density in a project is to build a concrete podium below the wood frame. Since wood is more cost-effective and cannot be above five or four stories using Type IIIA or Type VA construction types, building the wood frame on top of the podium (referred to 5 over 1, 4 over 1) may be seen as more attractive. Wooden Skyscraper? In November 2015 the University of British Columbia in Vancouver, Canada began construction on what will be the tallest wood building in the world. Opening in 2017, it will provide student housing for 404 students. Designed by Acton Ostry Architects, the building costs $51.5 million, approximately $127,000 per room. There are 17 stories of mass timber built on a one story concrete podium. In order to construct a wooden structure at that height, the use of engineered wood was required, specifically cross-laminated timber (CLT). CLT is made “from layers of timber sections glued together with their grains”—the longitudinal arrangement of wood fibers—“at right angles to one another”. Beyond the Wooden Skyscraper At some point in the future, your optimism determining when, researchers hope to build structures using carbon nanotubes. If successful, carbon nanotube technology is supposed to be stronger, lighter, and more durable than steel! Omar Kashef is a third-year graduate student seeking a dual-degree in Public Administration and Information Science and is currently a Fellow with the Development Finance Initiative. |

Published November 17, 2016 By CED Program Interns & Students

Did you know that the world’s oldest wooden structure is found in Japan, the Horyu Temple, and has managed to withstand rain, wind, and earthquakes for over 1,300 years? Although wood construction dates all the way back to Stone Age! For thousands of years’ humans have relied on wood to build structures because of its strength and durability.

The benefits to wooden structures are plenty. One, they weigh about a quarter of the weight of equivalent concrete material thus requiring a smaller foundation. In downtowns with decreasing land and increasing land costs, this could be a major benefit. Plus, building with wood can be cheaper and wood structures act as CO2 sinks absorbing and storing carbon dioxide emissions. Although wood is costlier per cubic foot than steel-and-concrete, building with timber is faster potentially resulting in a cheaper construction cost overall and boosts the efficiency of the building.

Ultimately, building with wood makes more economic sense the taller the building. There are plans for wooden skyscrapers upwards of eighty stories! One Vancouver architect, Michael Green, likened the current age “to the beginning of the steel revolution 120 years ago.” Regardless, many American cities do not allow wood structures past 5 stories.

Multifamily Construction

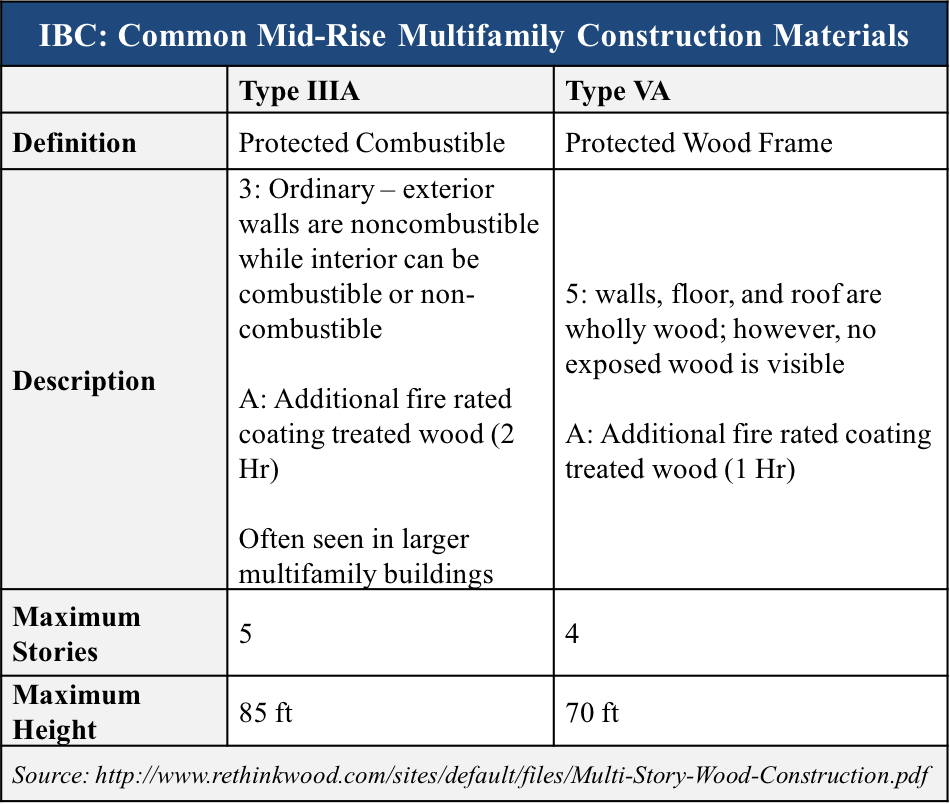

The International Building Code (IBC) is a building code model that has been adopted by most of the United States. This code outlines the constraints of different construction materials used in mid-rise buildings. While there are other construction types, the following table represents more reasonable multifamily construction types for products likely to be built across NC.

One way to boost density in a project is to build a concrete podium below the wood frame. Since wood is more cost-effective and cannot be above five or four stories using Type IIIA or Type VA construction types, building the wood frame on top of the podium (referred to 5 over 1, 4 over 1) may be seen as more attractive.

Wooden Skyscraper?

In November 2015 the University of British Columbia in Vancouver, Canada began construction on what will be the tallest wood building in the world. Opening in 2017, it will provide student housing for 404 students. Designed by Acton Ostry Architects, the building costs $51.5 million, approximately $127,000 per room. There are 17 stories of mass timber built on a one story concrete podium. In order to construct a wooden structure at that height, the use of engineered wood was required, specifically cross-laminated timber (CLT). CLT is made “from layers of timber sections glued together with their grains”—the longitudinal arrangement of wood fibers—“at right angles to one another”.

Beyond the Wooden Skyscraper

At some point in the future, your optimism determining when, researchers hope to build structures using carbon nanotubes. If successful, carbon nanotube technology is supposed to be stronger, lighter, and more durable than steel!

Omar Kashef is a third-year graduate student seeking a dual-degree in Public Administration and Information Science and is currently a Fellow with the Development Finance Initiative.

Author(s)

Tagged Under

This blog post is published and posted online by the School of Government to address issues of interest to government officials. This blog post is for educational and informational Copyright ©️ 2009 to present School of Government at the University of North Carolina. All rights reserved. use and may be used for those purposes without permission by providing acknowledgment of its source. Use of this blog post for commercial purposes is prohibited. To browse a complete catalog of School of Government publications, please visit the School’s website at www.sog.unc.edu or contact the Bookstore, School of Government, CB# 3330 Knapp-Sanders Building, UNC Chapel Hill, Chapel Hill, NC 27599-3330; e-mail sales@sog.unc.edu; telephone 919.966.4119; or fax 919.962.2707.